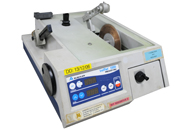

| DIAMOND SAW CUTTER | CROSS SECTION POLISHER | POLISHER AND GRINDER |

** Now Constructing **

In the CP, a shielding plate is mounted on the upper portion of the specimen, and then the portion protruding from the shielding plate is irradiated with a Broad Argon Ion Beam, this procedure enables a cross section to be prepared along the edge of the shielding plate. Compared with mechanical polishing, the CP easily creates a highly uniform cross section with no strain caused by milling.

Specifications

Gas for ion

Argon gas

Gas flow control

Mass flow controller

Pressure measurement

Penning gauge

Evacuation equipment

Turbo molecular pump. Rotary pump

Main Applications

- Sample preparation by grinding and polishing are used to create a flat, defect-free surface

- For examination of a metal's microstructure under a microscope .

- For checking the thickness of plating layer.

Specifications

- 8" (203mm) or 10" (254mm) grinder/polisher

- Quiet belt drive systems

- Upgrade to Semi-automatic systems with addition of Vector or Vector LC Power Head.