SELECTIVE PLATING

The main use of selective plating is to focus plating on the functional area, thus bringing down plating costs. The area of a part not to be plated is masked so that it is not plated. Epson is currently providing two types of selective plating: nickel and silver. We also work closely with our customers to provide customized solutions that meet and exceed their expectations.

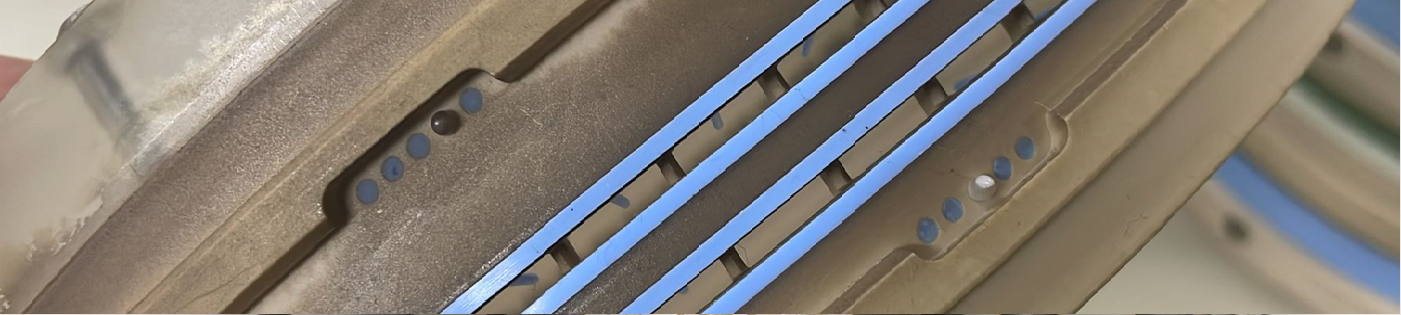

Selective Nickel Plating

- Selective nickel plating is used for high-pressure turbine support assemblies, which are plated at a minimum thickness of 500µm. Unplated areas are masked with masking tape during the plating process.

Main Application/Advantages

- Epson has developed a new plating production line concept that reduces the time taken from days to hours, uses a smaller solution tank and delivers better quality.

Generic Process Flow

Non-Bath Selective Plating (NBS)

- Non-bath selective plating (NBS) is performed using Epson's self-designed machine, which has a solution agitation system specialized for selective plating. The internal diameter of the part to be plated is used as a bath, while any non-plated areas are covered with a rubber mask. The bath level is automatically controlled and the loading jig and rubber mask are specially designed to cater to different sizes.

Main Application/Advantages

- NBS is used for selective silver plating. Using this method allows the special anode to control the distribution of the plating thickness, from 1~50 µm. NBS also helps to conserve chemicals and energy, thus making it environmentally friendly.

Generic Process Flow

Refer to related pages

Aerospace/Oil & Gas, Nickel Plating, Silver Plating