Palladium, pink gold and DLC plating are used in the watch industry, and are applied to watch cases and parts. Palladium is valued as a decorative metal, as well as for its wear and corrosion resistance and its durability. Pink gold is used for its appearance and its wear resistance.

| PVD Coating for Watch Case and Parts |

|

Using PVD Sputtering Technology, it has Good Hardness and Scratch Resistant. Can be Used for Decorative Purposes, Tools, Jewelry and etc.

| Specifications |

| Substrate: |

Ti, Stainless Steel |

| Sputtering Thickness: |

Ti: 0.1µm, Cu: 0.3~2µm,

Diamond Like Carbon (DLC ): 0.5~2µm |

| Metallization: |

Ti-Cu

DLC - Diamond Like Carbon |

| Thickness: |

0.1 - 5µm (±20%) |

| DLC Hardness: |

30 - 60GPa |

| DLC Friction coefficient: |

0.01 - 0.05 |

| Coating Applications |

| Coating |

Thickness |

Hardness |

Friction coefficient |

Heat Resistance |

| TiN |

2~6 µm |

2500 Hv |

0.65 |

600 °C |

| TiCN |

2~6 µm |

4200 Hv |

0.3 |

400 °C |

| TiAlN |

2~6 µm |

4500 Hv |

0.07~0.3 |

750 °C |

| CrN |

2~6 µm |

2500 Hv |

0.2 |

700 °C |

| DLC |

0.01~2 µm |

>2500 Hv |

0.05~0.2 |

250 °C |

| Technical Challenges |

TiC

Uniformly Exhibit a Variety of Colors, Excellent Adhesion and Good Hardness |

Various Decorative Colors |

DLC-Diamond Like Carbon Coating

High hardness (>40GPa), Low Friction Coefficient and Good Wear Resistance |

The world's first off-body protector structure The world's first off-body protector structure

Developed in 1975 as the World's First Body Protector. It was developed for its highly Reliable Shock Resistive and Safety feature on Diver's Watch. In 1986, ceramics material was used for the Quartz Models of 100M Diver Watch and characteristics of being light weight, high corrosion-resistant and high hardness. |

Can be Plated on Cutting Tools |

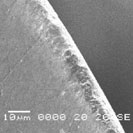

The cross section of tool after cutting |

Please refer to the relevant pages

Copper Plating,PVD

|

| Plating for Watch Case and Parts |

|

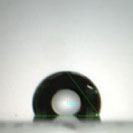

Plating technique using a constant voltage on the case to avoid the double layer and coating roughness.

| Specifications |

| Substrate: |

Brass,Stainless Steel,Fe |

| Metallization: |

Au, Rh, Ni, Pd, Cu, Pink Gold, Bi-Color Plating |

| Thickness: |

2.8 - 3µm |

| Technical Challenges |

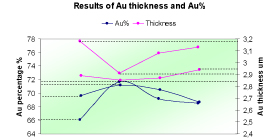

| Improved Wear Resistance and Control for Differences in Constant Voltage and Current. |

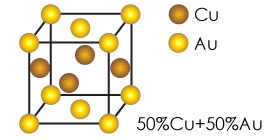

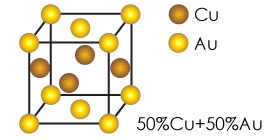

AuCu--Type I superstructure Hardness 400~500Hv |

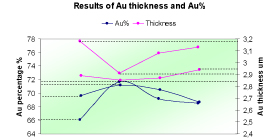

Difference in the Constant Voltage and Current to the Difference in Percentage of Gold to the Thickness of Gold. |

Please refer to the relevant pages

Gold Plating, Rhodium Plating, Palladium Plating, Nickel Plating, Copper Plating

|

| FPC Reel to Reel Selective Plating |

|

Au Spot Plating on Flex Tape for Wire Bonding of Watch Parts

| Specifications |

| Substrate: |

Flex Tape |

| Metallization: |

Au |

| Thickness: |

IL = >0.5µm, Non-Critical Area=>0.05µm |

| Technical Challenges |

Reduced Usage of Gold at Selected Plated Area

Electroplating requires portion 0.5μm (0.1% area), while other portion 0.05μm (99.9% area) |

Please refer to the relevant pages

Gold Plating

|

![]()