| WASTE EN RECOVERY SYSTEM | INK WASTE RECYCLING SYSTEM | WASTE WATER REUSE SYSTEM | KMnO4 RECYCLING TECHNOLOGY | HCl RECYCLING TECHNOLOGY | SOLAR ENERGY REGENERATION SYSTEM |

| KMnO4 RECYCLING TECHNOLOGY |

|

In the electroplating process, the oxidation of the substrate material is not conducive to the plating, before we deal with the substrate material to the substrate material pre-processing. This process is called bright dipping for steel materials, will immerse the metal in a solution of KMnO4. However, the chemical reaction of the removing of the surface oxide consume a lot of KMnO4.

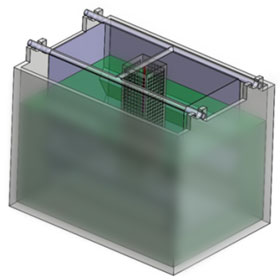

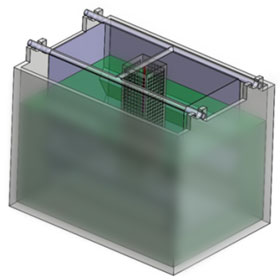

Epson has developed a KMnO4 regeneration system, through recycling, reprocessing, so that companies can greatly reduce the cost of processing.

| Specifications (Can be Customised to Customer Requirements) |

| Size: |

500 (L) × 300 (W) × 500 (H) |

| Treatment Volume: |

800L and more |

| Concentration Range before treated: |

KMnO4 : 15g/l, K2MnO4 : 50 g/l and more |

| Concentration Range after treated: |

KMnO4 : 45g/l , K2MnO4 : 20 g/l and more

(300% Regeneration), |

| Treatment Time: |

6 hours or more depend on treatment volume |

| Capacity: |

KMnO4 : 24kg per treatment or more

(Subjected to treatment vol) |

| Advantage |

Per hour Processing of 3g / l Per hour Processing of 3g / l

|

Reduced 50% of Industrial Water Reduced 50% of Industrial Water

|

Very Small Covering Rate Very Small Covering Rate

|

Easy Installation Easy Installation

Operates Safely

|

Reduces Cost Reduces Cost

|

Back To Top

|