Singapore Epson Industrial Plating Division offers unique plating technology for various industries. Each plating method is customised to meet various sizes of different parts. Because we follow strict specifications according to customer requirements with our advanced technology, this is how we differentiate ourselves and in the operation process reducing harmful effects to the environment.

Read how we managed to reduced harmful environmental effects here

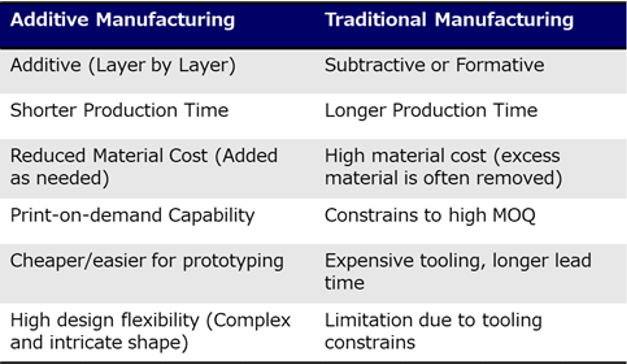

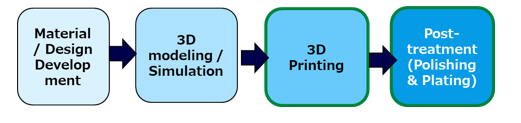

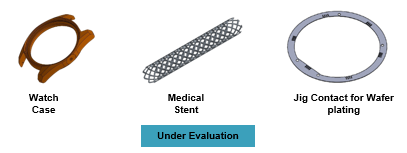

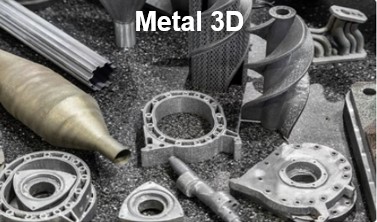

| 3D printing (Additive Manufacturing) | ||||||

|

Providing one-stop service to customers and end users by integrating our plating division's unique surface treatment technology (Wet coating and PVD dry coating) into our plating division's existing plating business.

|

|||||

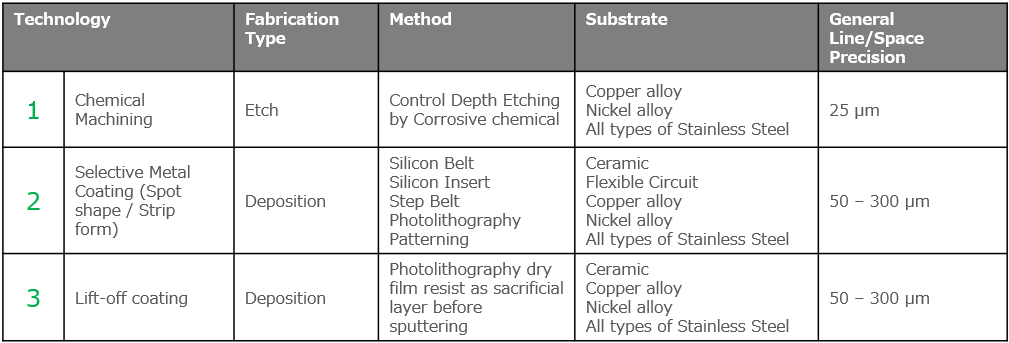

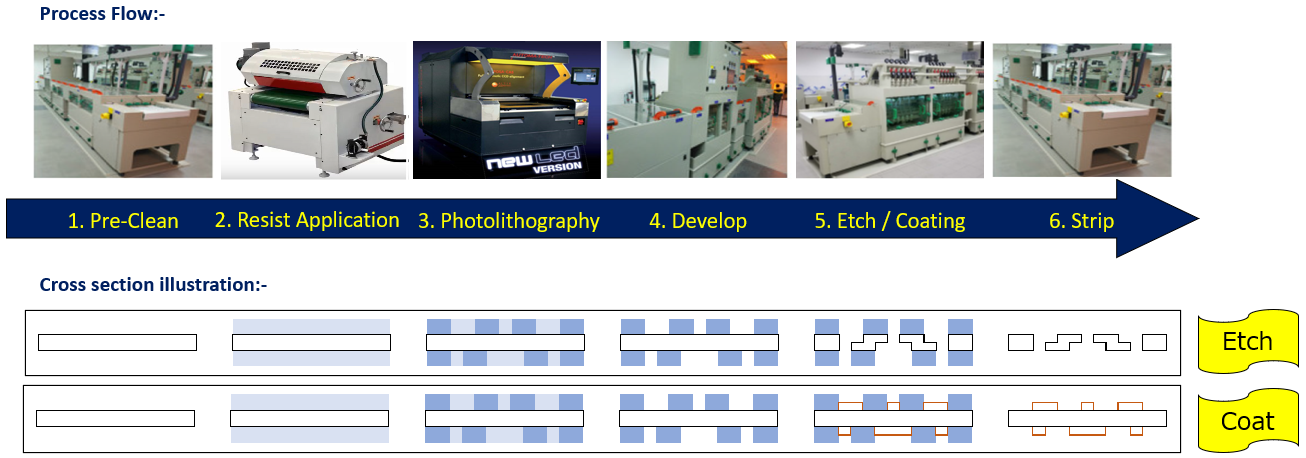

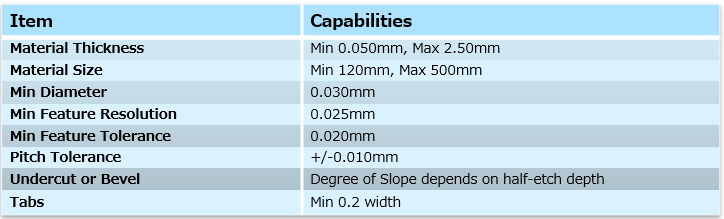

| Microfabrication | ||||||

|

Microfabrication by Photo Chemical Etching Process is a highly precise, tightly controlled corrosion process used to produce complex metal components with very fine detail.

|

|||||

| DLC Coating | ||||||

DLC -Diamond Like Carbon Coating

Blades, drill bits and mould |

By applying filtered cathodic vacuum arc technology, this machine can deposit DLC(Diamond Like Carbon) coating with extreme hardness and low friction for superior wear resistance, which can be applied to prolong lifespan for cutting tools, gears, shaft bearings, mould etc. DLC coating can also be applied for decoration coating like watch bands, watches cases.

|

|||||

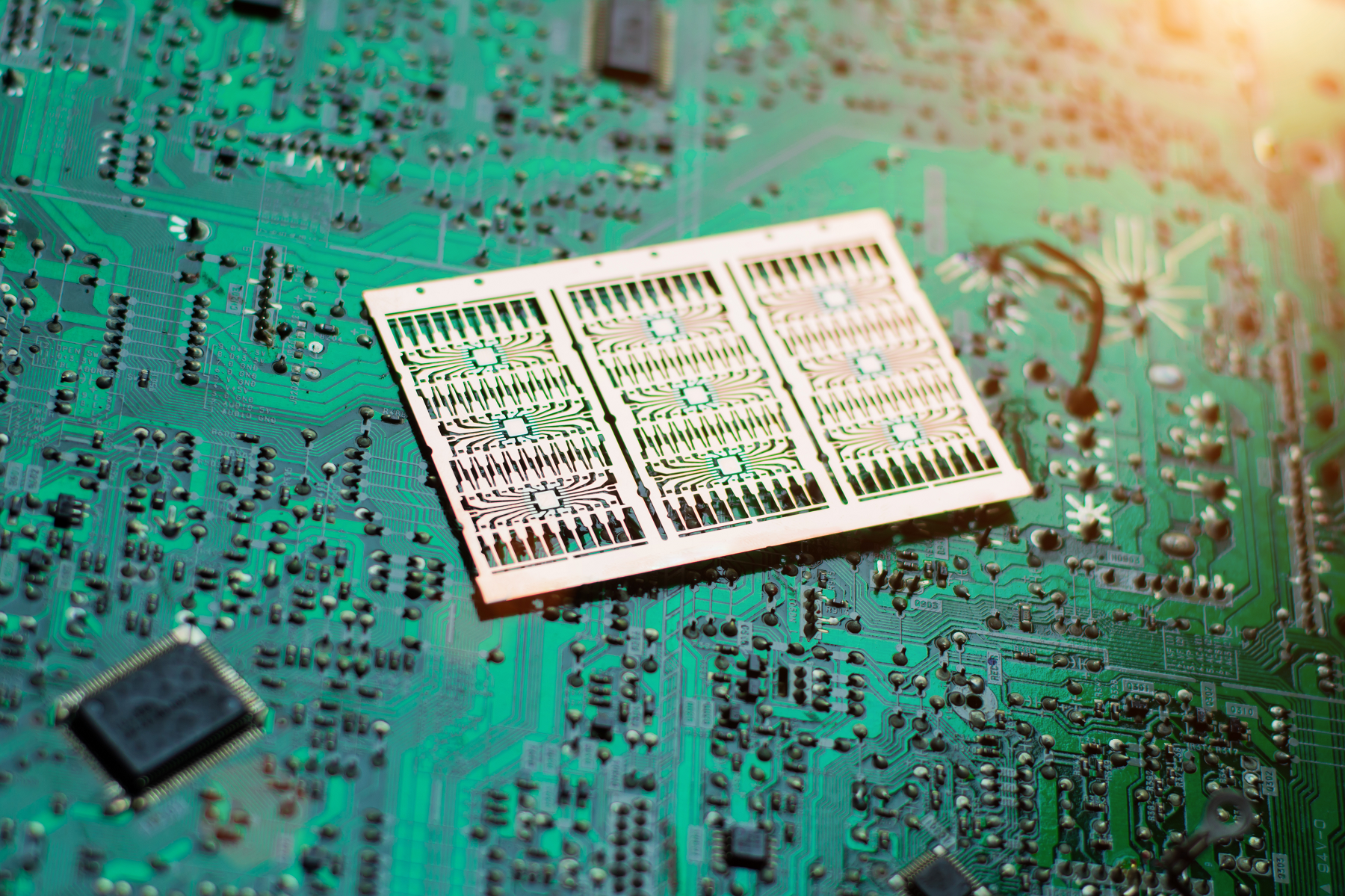

| Multi-Target Sputtering | ||||||

Sputtering |

The Multi-target sputtering system designed with multi-targets (4 targets) inside the process chamber, suitable for R&D, prototype sputtering or small scale production for wafer and panel products.

Machine is also configured with a load lock, which enable users to load/unload products without breaking the vacuum of process chamber

|

|||||

| Barrel Sputtering | ||||||

Loading   Sputtering   Unloading |

The barrel sputtering machine is designed with a rotating barrel in which products are loaded for sputtering process. The barrel sputtering process enables high loading quantity and great productivity for loose/small size metallisation.

|

|||||

| Vibratory Plating | ||||||

Vibro-Barrel |

We offers vibratory plating service to bulk process delicate work piece as alternative to barrel plating. Vibratory plating is designed to prevent entanglement, deformation, scratches and other mechanical defects on work piece. It is commonly employed in plating of pin, switch, connector and terminal. Plating finishes available including nickel, silver, palladium and gold.

|

|||||

| Selective Plating Technology | ||||||

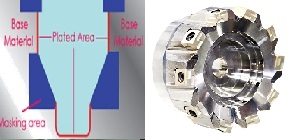

Reusable, Easy Handling Masking Used During Plating Process. |

The main use of selective plating is to focus plating on the functional area, thus bringing down plating costs. The area of a part not to be plated is masked so that it is not plated. Epson is currently providing two types of selective plating: nickel and silver. We also work closely with our customers to provide customized solutions that meet and exceed their expectations.

|

|||||

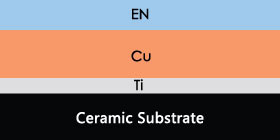

| Wet and Dry Combined Deposition Techology | ||

Three Layered Plating |

The combination of both wet and dry deposition technique, this unique technology is plating three layers on a non-metallic substrate, currently used in the semiconductor industry. This unique technology is a One-Stop plating services provided by Singapore Epson Industrial Plating Division. A Vacuum deposition acts as a seed layer is plated on non-metallic surfaces to allow further surface processing. This combination tTechnology allows Singapore Epson Industrial Plating Division to provide customers with unique and customised plating solutions. Please refer to the relevant pages Semiconductor Industry |

|

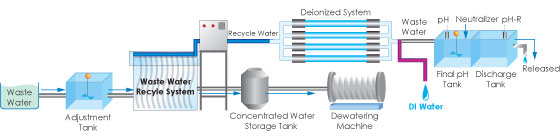

| Waste Water Reycling System | ||

|

Plating can be used in a variety of environmental control systems related to waste water treatment, including DI systems and water recycling systems. Epson's cyanide treatment line is used to treat all cyanide, gold and alkaline waste from production, and can treat approximately 222m3 of waste daily. Epson also has a heavy metal treatment line to treat all metallic and acidic production waste, and can treat approximately 278m3 of waste daily. These systems allow users to maintain trade effluent treatment facilities in good order and allow for quality trade effluent that exceeds PUB's regulatory and environmental requirements. Epson is working to improve the current chemical coagulation to electro-coagulation method for waste water treatment in order to minimise chemical usage and waste. Another system that Epson has developed is the DI system, which has been used as the feed source for water generation. The system is able to generate three different types of DI water (RO, LP and HP) to meet production needs using Ultra Filtration and an RO system. The DI system can produce approximately 528m3 with less than 20us of quality water daily to ensure an uninterrupted quantity and quality of DI water supply. -> µS (micro Siemens) Epson's in-house water recycling system has proved to be a cost-effective and efficient way to reduce our water consumption. The system minimises chemical usage and the strain on natural resources, conforming to Seiko Epson's environmental policies and focus on water conservation. The result has been an approximately 40% recycling rate for production waste water. In addition, we also have a rainwater collection project in place. Epson is currently working to achieve zero trade effluent discharge by recycling all effluent.  Operation Process |

|