| ICP ATOMIC EMISSION SPECTROMETERS | GLOW DISCHARGE PROFILER | XRF THICKNESS COATING GUAGE | ELECTRON DISPERSION |

ICP ATOMIC EMISSION SPECTROMETERS

Simultaneous ICP atomic emission spectrometers are next-generation systems that offer the superior accuracy necessary to simultaneously and quickly analyse multiple elements regardless of their concentration levels. They also feature user-friendly software that makes analysis easy. It represent the ultimate in ICP atomic emission spectrometry for environmental, pharmaceutical, food, chemical, metal, and other fields

Specifications

RF Generator

Frequency: 27MHz

RF Power: Max. 1.6kW (0.2 kW step)

RF Device: Transistor

Output Stability: Within ± 0.3%

Efficiency: 75% or better

Spectrometer

Echelle Optics:

Range of wavelength: 167nm to 800 nm

Dispersion elements:

Echelle grating 79 line/mm

Prism

Reciprocal dispersion:

0.21 nm/mm at 200 nm

0.68 nm/mm at 600nm

Resolution:

≤ to 0.005 nm at 200nm

Temperature:

termal controller (38 ℃ )

Atmospheric removal system:

Rotary vacuum pump ≤ 10 Pa

Device

CCD (charge coupled device) detector

Pixel number: 1024 x 1024 pixels (1-inch)

Pixel size: 20μm x 20μm

Cooling control:Peltier device

GLOW DISCHARGE PROFILER

Radio Frequency-Glow Discharge-Optical Emission Spectrometry (RF-GD-OES) from HORIBA can be used on both conductive and non-conductive materials. It can also analyze materials with even surfaces with diameters greater than 4mm. In total, 43 elements, including H, O, N, C and Cl, can be determined by using glow discharge (GD).

Main Application/Advantages

-

The main applications of GD analysis are for surface analysis, bulk analysis and depth profile analysis. For example, GD can be used to profile a Zn-Ni coating.

Specification

Resource

Radio Frequency

Detector

Optical Emission Spectrometer

Sample Shape

Plain, Diameter ≥ 4mm

Detection Limit

ppm (mg/L)

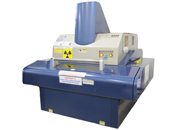

XRF THICKNESS COATING GAUGE

The XRF Thickness Coating Gauge uses a sensitive, non-contact, and non-destructive method to measure the coating thickness for metallic and non-metallic materials over a range of thicknesses, from as little as 0.05 μm to as much as 70 μm depending on the coating materials.

Main Application/Advantages

The thickness gauge is widely used to determine:

- The thickness of coated materials

-

Elements through spectrum matching

-

Thickness of material in cavities

-

Metallic elements in solutions

Advantages of this gauge include:

-

One-touch focusing operation with laser focus mechanism

-

Automatic measurement functions

-

Thin Film FP software (capable of a wide range of applications including multiple coated layers and Pb free allow coatings)

-

Report creation software (prints out a report of measurement results through macro-enhanced software)

-

Fast, reliable and accurate measurement

Specifications-

Able to determine at least 35 types of electroplated layers; i.e. Au, Ag, Pd, Pd-Ni, Ni-B, Ni-Co, etc.

-

Measures over a wide spectrum of elements from titanium to bismuth

-

Collimator size as small as 0.05mm for smaller measurement areas

-

Please refer to Scanning Electron Microscope